Change Language :

Save on cables with the price check

Tech up, cost down. It's our job.

Safely replace PUR with cost-effective PVC

PUR (polyurethane) has decisive advantages as a jacket material in some areas, but not in all. Our aim is to provide enough information so that you can decide objectively whether a cable with PVC jacket is not only sufficient, but may be a better solution.

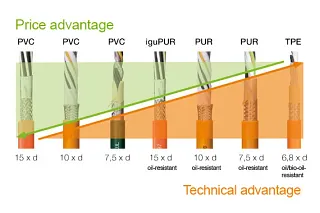

How do you save money by choosing the right outer jacket?

Every material has specific specifications; there is no one-size-fits-all good or bad material. Here we use the example of the PVC and PUR jacket materials to show which is best suited for what applications and provide specific ideas for reducing costs in this context.

Advantages and properties of the two materials

Sample calculation of catalogue cables

Application examples from practice

Today, servo cables are the standard for drive technology in automation technology and mechanical engineering. The movements to which the cables are subjected to in these industries are associated with high mechanical stress. In addition, the cables are often used in environments contaminated by moisture, oils, dust or swarf. Choosing the right jacket material is therefore crucial. In order to ensure the consistent quality of the jacket material, our cables are repeatedly tested under real conditions so that we can provide a binding guarantee and calculate the cable online. The cables are tested in both short-term batch tests and long-term service life tests.

Example of long-term test 3841a of a servo cable of the CF21 series (PVC cable), with a test bend factor of only 6.1 x d and 54 million completed strokes.

Test 3841a servo cable CF21. UL

However, it is not only our servo cables that offer this choice between different jacket qualities, but also all our other cable types, such as measuring system cable, bus cable, control cable, etc., all of them tested in our in-house test laboratories.

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 09:00 - 17:00

Online:

24h