Change Language :

Rolling bearings

Ball bearing types at igus

The ball bearing is the most commonly used type of rolling bearing. Our plastic ball bearing types are already being used successfully in numerous customer applications worldwide. From radial deep groove ball bearings, thrust bearings and ball transfer units to conveyor rollers and other types of rolling bearing: We supply the solution for the most specialised applications. And if a standard part does not fit, our customers can always fall back on our special rolling bearing parts. Our experts support projects from the initial idea right through to the customised end product.

Radial deep groove ball bearings

Special designs

Questions about rolling bearings

The various influences that affect the service life of a bearing are relatively trivial. It goes without saying that a lorry load of fine dust is less conducive to a long bearing life. The fact that an ambient temperature of 500°C can cause difficulties when choosing the right lubricant does not raise many eyebrows in surprise. And yet, in view of the many technical requirements placed on assemblies and the often far too subordinate role that bearings play in these assemblies at the end of the development process, it is often difficult to keep an eye on the essentials. What are the important influencing factors? When should I choose a rolling bearing and when would a plain bearing perhaps be preferable? Which are better suited to certain influencing factors? Let's take a closer look here.

Plain or rolling bearing: Speed and types of movement

A bearing arrangement would not be a bearing arrangement if no movement occurred. For this reason, this point is at the top of the list. This is despite the fact that the question of load-bearing capacity is actually the one that is asked first in practice. Strange, actually. But to the point. The first decisive question is, of course, the type of movement that takes place. Is it designed to rotate? Or only swivel back and forth at a certain angle? Quickly? Or slowly? What does "fast" mean to you? One rotation per 2 minutes? Or 500 per second? And if so, how long at a time? 1 second? 1 hour? Permanently? Simple rule of thumb: For fast, continuous rotation, rolling bearings are more suitable than plain bearings. Plain bearings are also suitable for slow to medium speeds. For swivelling applications, where the bearings only have to perform fractions of a full rotation, plain bearings are often the better choice.

Material issues:

How great is the force acting on the bearing in relation to its cross section (i.e. bearing length x inner diameter)?

This is where the wheat is separated from the chaff – and not just in terms of materials. This is because often only the weight or the force acting on the bearing is mistakenly considered, but not the size of the bearing. The thousands of Newtons of load are often reduced to a surprisingly low pressure that actually acts on the material. The end result is the realisation that it does not automatically have to be an expensive and heavy plain bearing made of solid metal (another common misconception: Thicker walls = greater load-bearing capacity) just because the loads appear high at first glance. If the bearing point is sufficiently dimensioned, "softer" materials, which are often significantly cheaper and lighter, are also suitable.

What type of load is involved?

Without going into the dreaded mathematical drudgery of mechanics at this point: If it were purely a matter of compressive strength, most bearings would not be made of expensive metals or plastic, but of stone. Typically, loads at bearing points are not static (i.e. always the same level) and often do not act in one direction. They push and pull in different directions at the same time. They "shear" and "twist", alternate, surge and subside again, shake or strike. The mechanical terms here are "static and dynamic loads" for constant or alternating loads. Not only the compressive strength of a material is put under strain, but also the tensile strength, shear strength and flexibility. Suddenly, the hardest material is no longer the best, but rather the toughest.

Temperature

Completely unjustified, this point only comes in fourth place. Why is this unjustified? Because wear – and therefore service life – is not really about mere speeds or tensile tests on load test benches, but about heat. Frictional heat. It is not for nothing that the so-called pxv value plays such an important (although not the only) role. The functionality of a bearing is determined by the frictional heat generated. The greater the product of the acting pressure and the speed of movement, the greater the heat development. If more heat is generated than can be dissipated, the bearing point heats up and wears out or fails. The heat development in the bearing is not only influenced by the heat generated, but also by the thermal conductivity of the bearing material, the shaft and the bearing support, as well as the ambient temperature. These factors have a fundamental effect on the selection of bearing materials and any lubricants required.

Dirt and dust

Depending on their quantity and composition, neither is helpful for bearing points of any kind. Whether plain or rolling bearing. Whether dry-operating or lubricated. However, as the different bearing types "suffer" from these influences to varying degrees and protective measures are more complex depending on the design, this point plays a not insignificant role. Complex sealing systems are often used to keep the lubricant in the bearing point and the dirt out of the bearing point. Another possibility is to continuously squeeze grease from the inside through the bearing point to the outside (the reason why grease can be seen oozing out of the pivot points on some heavy equipment). This is where lubrication-free systems can offer advantages or be easier to seal.

Contact with media

In connection with bearings, media contact is the umbrella term for chemicals and substances with which the bearing point comes into contact. It makes a significant difference whether the bearing point has to run under water or in gas or is cleaned regularly. A look at the media/chemical resistance tables for the relevant bearing materials can help here. Often, however, there is no way around tests under application conditions. In general, lubrication-free plastic bearings, whether in the form of plain bearings or rolling bearings, demonstrate their main advantages here. They are corrosion-free and do not require lubrication by volatile or externally supplied lubricants.

Mating partner

Finally, another point that is often underestimated – but which is more relevant for plain bearings than for ball bearings: Plain bearings are usually designed so that a shaft moves in them while they themselves are fixed in a housing bore. The nature of the shaft is of particular importance here. Not only the surface roughness, but also the hardness of the surface play a major role. Especially for "softer" steels or aluminium, plain bearings made of plastic are more suitable than those made of metal. Surface hardening is often sufficient for optimum protection against wear.

A rolling bearing is a machine element that enables movement between two components by means of rolling bodies. These rolling bodies, also called rolling elements, can be balls, cylinders, needles or cones. Rolling bearings reduce friction and carry loads by transferring motion from the inner race to the outer race. Ball bearings are often referred to synonymously as rolling bearings, as ball bearings are the most commonly used type of rolling bearing and are a special type of rolling bearing. The balls only have point contact with the raceways, which reduces friction. This makes them particularly suitable for high speeds. However, ball bearings have a lower load carrying capacity than other types of rolling bearing, such as roller bearings, which can carry higher loads due to their linear contact surface.

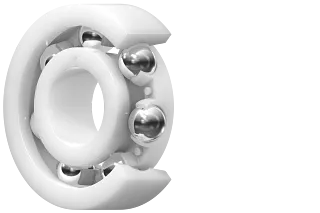

Cross section of a xiros plastic rolling bearing

The xiros rolling bearing structure is as follows:

Inner and outer race:

The suitability of a xiros plastic rolling bearing is largely determined by the materials of the two races. The low-friction ball bearings are manufactured from high-performance plastics with different material properties, allowing a wide range of applications to be covered and service life to be maximised.

Rolling bearing cage:

The cages of our rolling bearings are matched to the outer and inner race materials in terms of their resistance to chemicals and temperatures, resulting in optimised performance.

Rolling bearing balls:

In addition to stainless steel balls, balls made of glass, plastic or ceramic are also used. When selecting glass balls, attention should be paid to the absence of metal and chemical resistance criteria. Our rolling bearings are particularly lightweight due to the use of plastic as the main material. The stainless steel version is characterised by its cost-effectiveness and temperature resistance.

The types of rolling bearings are as varied as their possible applications. In addition to ball bearing types, there are other types that are designed for specific applications:

- Ball bearing: The most universal form of rolling bearing with balls as the rolling element.

- Roller bearing: Suitable for higher loads and equipped with cylindrical rolling elements.

- Needle roller bearing: Suitable for particularly compact designs, as the needles as rolling elements enable a low installation height.

- Thrust bearings: Developed to safely support axial loads.

The plastic rolling bearings from igus offer decisive advantages here: They are lightweight, maintenance-free and can be flexibly customised for different types and areas of application.

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 09:00 - 17:00

Online:

24h