Change Language :

Significantly reduce maintenance costs with predictive maintenance | i.Cee

Different production areas ...

smart plastic i.Cee - A whole lot of Industry 4.0 in one box

The white paper on predictive maintenance

Increase system availability and ensure process conformity

In the white paper, you can find out about the following:

- What is the difference between the two concepts?

- What technologies are behind the respective systems?

- What do both systems offer for energy supply in industry?

How does predictive maintenance work at igus?

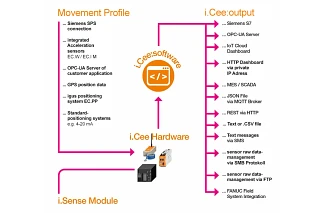

Only the smart networking of individual components creates the solid foundation for predictive maintenance concepts. At igus, we call our predictive maintenance system i.Cee.

The central element of this system is the i.Cee software. This software, combined with sensors on the energy chain, the plain bearing bushing or a linear carriage, transform stock products into smart products. This upgrade enables you to determine the maximum service life of your igus product and the i.Cee system specifies the perfect time for servicing. Algorithms adjust the service life and service time according to usage. With the software provided by us, a few sensors and the new i.Cee:plus II communication module, standard products available from stock can be turned into smart energy supply systems or bearing technology in no time at all.

You alone decide on the route & access of the data

Data transfer within your local company network (i.Cee:local) or via the secure cloud (i.Cee:cloud)

Complete overview of smart plastics

Insight into the complete product portfolio for Industry 4.0

Table of contents:

- Condition monitoring (i.Sense)

- Condition monitoring products

- Application examples of condition monitoring

- Predictive maintenance (i.Cee)

- Application examples for predictive maintenance

- How does the data flow with predictive maintenance?

Tested in the test laboratory for use in the real world:

The huge motion plastics sample box

Trying things out made easy: With the igus corner, you always have the latest motion plastics right at hand that are individually tailored to your industry.

We will bring the display to you, set it up on request and fill the compartments with the products of your choice. Or you can set it up yourself. As a permanent exhibition or for a limited period.

This could also be of interest to you:

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 09:00 - 17:00

Online:

24h