Change Language :

Safe and reliable in any weather

The challenge

The Ecological-Botanical Garden at the University of Bayreuth has unique facilities that are used by scientists for experiments and long-term studies. On 16 hectares of open space and 6,000 square metres of greenhouse area, the garden presents near-natural types of vegetation from all over the world and, in addition to the diversity of plants, illustrates their ecological relationships and functions. One of the facilities in the Ecological-Botanical Garden is the lysimeter facility. With 28 individual test basins, it offers the opportunity to quantify the water, nutrient and carbon balance of agricultural crops. The facility is also equipped with a rolling greenhouse that automatically covers part of the planted basins when it rains, thus keeping out precipitation. In this way, experiments can be carried out with controlled drought stress, which is particularly urgent in view of the increasingly frequent periods of drought. "As part of a new research project, we had to modernise the roller greenhouse at the lysimeter facility, as it was no longer functional and no longer met today's safety requirements," explains Holger Quindt, Electrical Engineering Officer at the University of Bayreuth.

Solution

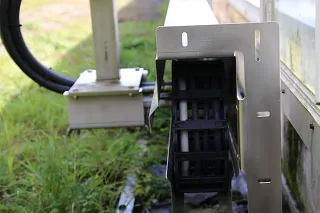

"We wanted a clean and future-proof solution for the energy supply in the fully automated roller greenhouse, which is why we jointly decided in favour of a basic flizz® complete system," says Oliver Köhler, sales engineer at igus®. "Apart from that, there was no alternative to using an e-chain® from our point of view, as a busbar system is not recommended for outdoor use due to weather conditions and signal transmission. Alternatives such as a trailing cable or a festooning system would have been too maintenance-prone and, in this case, too expensive. Our E2/000 series energy chain was the ideal choice for this application. It is cost-effective, easy to install, very robust and runs quietly over long travel distances of up to 150 metres." The basic flizz® is a complete system and consists of an energy chain, which is filled with the highly flexible chainflex® cable from igus® and guided safely and smoothly in a weatherproof stainless steel housing. The basic flizz® system is designed to protect the cable from dirt and extreme weather conditions. The travel of the fully automated roller greenhouse at the University of Bayreuth is around 21 metres. To compensate for misalignments, a floating moving end was also installed to further extend the service life of the entire application. The experts at igus® decided to use the chainflex® control cable CF9, CF10 and CF77.UL.D as well as the motor cable CF34.UL.D due to the cross section and the number of cores. All cables are UV-resistant and designed for the highest loads. "We have the largest test laboratory in the industry, where we carry out over ten billion test cycles per year with energy chain and chainflex® cable. This enables us to guarantee reliable reliability, even with long travel distances, many cycles and the most extreme environmental conditions," says Oliver Köhler.

Quick and easy installation

Another advantage of the basic flizz® system is its simple and easy installation. "We dismantled the old drag chain, disposed of the cable and prepared everything for installation. The chainflex® cables were delivered to the university pre-assembled with the e-chain® and we assembled the entire system in one day with the help of an igus® fitter - including the trough, e-chain®, cable and stainless steel housing. The components of the system are perfectly coordinated, the cable lengths up to the control cabinet were precisely adhered to and the e-chain® with the cables runs safely and centred in the trough. The easy and versatile assembly of the igus® e-chain® in combination with the high stability and long service life of the chainflex® cable impresses us every time," Otto Schmidt is pleased to report. The pre-assembly also offers various advantages. Oliver Köhler adds: "When automating machines and systems, there are a number of different reasons to opt for pre-assembled energy supply systems. Production costs are reduced, sources of error are virtually eliminated, project planning costs are reduced and reliability is significantly increased." Holger Quindt from the University of Bayreuth concludes: "We now have a perfect solution. The roller greenhouse runs completely automatically, safety is guaranteed thanks to igus® and GERLITZ, and we now have a future-proof system that we will enjoy for a long time to come."

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 09:00 - 17:00

Online:

24h