Change Language :

drylin® R - Technical information

Material data table

| General properties | Unit | iglidur J | iglidur X | iglidur J200 | Testing method |

|---|---|---|---|---|---|

| Density | g/cm³ | 1.49 | 1.44 | 1.72 | |

| Colour | yellow | black | dark grey | ||

| Max. moisture absorption at +23°C/50% room humidity | % weight | 0.3 | 0.1 | 0.2 | DIN 53495 |

| Max. moisture absorption | % weight | 1.3 | 0.5 | 0.7 | |

| Coefficient of sliding friction, dynamic against steel | µ | 0.06-0.18 | 0.09-0.27 | 0,11 - 0,22 | |

| pxv value, max. (dry) | MPa x m/s | 0.34 | 1.32 | 0.33 |

| Mechanical properties | |||||

|---|---|---|---|---|---|

| Flexural modulus | MPa | 2,400 | 8,100 | 2,800 | DIN 53457 |

| Flexural strength at 20°C | MPa | 73 | 170 | 58 | DIN 53452 |

| Compressive strength | MPa | 60 | 100 | 43 | |

| Maximum recommended surface pressure (20°C) | MPa | 35 | 150 | 23 | |

| Shore D hardness | 74 | 85 | 70 | DIN 53505 |

| Physical and thermal properties | |||||

|---|---|---|---|---|---|

| Max. long-term application temperature | °C | +90 | +250 | +90 | |

| Max. short-term application temperature | °C | +120 | +315 | +120 | |

| min. application temperature | °C | -50 | -100 | -50 | |

| Thermal conductivity | [W/m x K] | 0.25 | 0.6 | 0.24 | ASTM C 177 |

| Coefficient of thermal expansion (at 23°C) | [K-1 x 10-5] | 10 | 5 | 8 | DIN 53752 |

| Electrical properties | |||||

|---|---|---|---|---|---|

| Specific transitional resistance | Ωcm | > 1013 | < 105 | > 108 | DIN IEC 93 |

| Surface resistance | Ω | > 1012 | < 103 | > 108 | DIN 53482 |

| General properties | Unit | iglidur E7 | iglidur A180 | Testing method |

|---|---|---|---|---|

| Density | g/cm³ | 1.05 | 1.46 | |

| Colour | dark grey | white | ||

| Max. moisture absorption at +23°C/50% room humidity | % weight | 0.1 | 0.2 | DIN 53495 |

| Max. moisture absorption | % weight | 0.1 | 1.3 | |

| Coefficient of sliding friction, dynamic against steel | µ | 0.05-0.23 | ||

| pxv value, max. (dry) | MPa x m/s | 0.31 |

| Mechanical properties | ||||

|---|---|---|---|---|

| Flexural modulus | MPa | 1,477 | 2,300 | DIN 53457 |

| Flexural strength at 20°C | MPa | 22 | 88 | DIN 53452 |

| Compressive strength | MPa | 78 | ||

| Maximum recommended surface pressure (20°C) | MPa | 18 | 28 | |

| Shore D hardness | 61 | 76 | DIN 53505 |

| Physical and thermal properties | ||||

|---|---|---|---|---|

| Max. long-term application temperature | °C | +70 | +90 | |

| Max. short-term application temperature | °C | +90 | +110 | |

| min. application temperature | °C | -50 | -50 | |

| Thermal conductivity | [W/m x K] | 0.25 | ASTM C 177 | |

| Coefficient of thermal expansion (at 23°C) | [K-1 x 10-5] | 11 | DIN 53752 |

| Electrical properties | ||||

|---|---|---|---|---|

| Specific transitional resistance | Ωcm | < 1012 | DIN IEC 93 | |

| Surface resistance | Ω | > 109 | < 1011 | DIN 53482 |

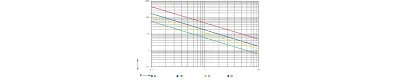

drylin® R - Comparison of the permissible dynamic load with the same diameter

X = velocity v [m/s]

Y = F [N] Ø [mm]

A = unsupported shaft -steel/stainless steel

B = self-supporting shaft - hard anodised alum.

C = supported shaft -steel/stainless steel

D = supported shaft - hard anodised alum.

diagram. 01: drylin® R - Comparison of the permissible dynamic load with the same diameter

drylin® R linear plain bearing

Dirt-resistant

The cylindrical standard bearings consist of a replaceable iglidur® J sliding film, which is clipped positively into an anodised aluminium adapter. The axial retention of the sliding film is realised via an annular groove.

The drylin® linear plain bearings are also available in solid plastic with the same dimensions. They are made entirely of the wear-resistant material iglidur® J and can offer technical advantages in addition to the significant price advantage. For example, applications in which machine parts are mainly made of stainless steel, such as food and filling technology, are predestined for the use of solid plastic bearings. A further weight saving is also easy to realise.

Both versions are designed for mounting in housing bore with tolerance H7. As with ball bushings, they are fastened using circlip according to DIN 471/472.

The narrow type of the cylindrical linear plain bearing, type 02, is pressed or glued into the H7 housing bore. Commercially available 2-component adhesives can be used for this purpose.

Dirt, dust, fibres

An important difference between all the linear bearings on offer is their compatibility with dirt. For most systems, the use of wipers or seals is recommended even with low levels of dust.

No other system offers such a high level of protection against dust, fluff and coarse dirt as drylin®. The absence of lubricants and the special design of the bearing surfaces with individual raceways and the interruptions between them have a particularly favourable effect in the event of contamination. Dirt, even if it is wet on the shaft, is wiped off the individual raceways and pushed back into the non-contact tracks. The crossbar of the running surfaces of the drylin®-bearing then glide on the track that has been wiped free of all dirt.

Split linear bearings

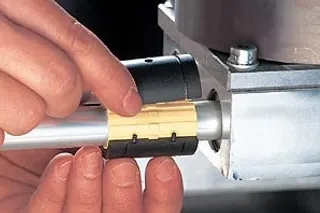

Applications at the limits of what is technically feasible or in extremely abrasive environments are characterised by the regular replacement of the bearing. In many cases, drylin® has been able to multiply the operating time. Nevertheless, it may be necessary to replace the bearing from time to time in such applications. drylin® linear plain bearings can contribute to considerable cost reductions in these cases, as only the bearing film needs to be replaced. This often saves costs of more than 90 %. There is also no need to remove the shafts.

The separable bearings are simply pulled out of the housing and opened. The sliding film is slotted and can be easily fitted to the shaft. Put the bearing halves back together, install - done. Assembly times can be reduced to a minimum with this programme of separable drylin® bearings.

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 09:00 - 17:00

Online:

24h