Change Language :

Multi-axis systems: positioning and movement systems from drylin®

maintenance-free XY table and linear robot

Lubrication-free linear axis

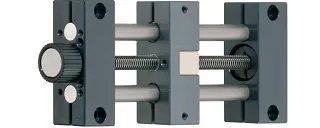

If you want to build a multi-axis system yourself, you can choose from a large selection of linear axis, which are driven either by trapezoidal thread, steep thread or toothed belt. From lightweight all-plastic units to solid stainless steel solutions - there is a solution for all individual requirements. The stroke length can be freely selected for all systems and the drive can be realised as an option or with motors.

Customer application examples

More information

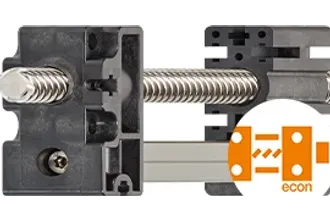

Suitable entry-level models | drylin® econ

Here you will find cost-effective linear modules for positioning and adjustment tasks.

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 09:00 - 17:00

Online:

24h