Change Language :

Labelling machines

Labelling overview

Various processes such as stretch or shrink technology can be used for labelling. Linear and rotary bearing products as well as energy chains from igus® are used in various areas that have to fulfil numerous requirements such as high precision and wear resistance, freedom from lubricants, corrosion resistance or resistance to cleaning agents.

Products used and application examples

Using the Sleevematic TS from Krones AG as an example, the various stations of modern labelling machines and the igus® products used in them are shown below: The polymer products perform a wide variety of tasks such as the cross and height adjustments of the sleeve brush, belt station or the infeed and outfeed sensors.

Customer application examples

Format adjustment of the 600 kg labelling block

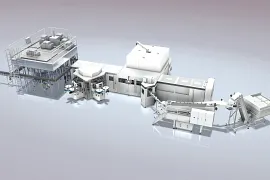

The compact filling system "InnoPET TriBlock" from KHS works with our sliding, linear, ball bearings and linear tables.

Go to user report

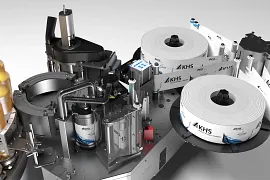

Wear-resistant labelling machines

Numerous rotary and linear bearings from our product range are installed in the labelling machines from KHS GmbH.

Go to user report

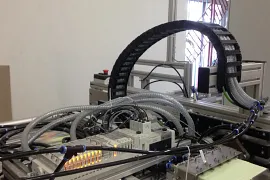

Cable guide for labelling machine

This labelling machine retrieves labels from the supply, applies the adhesive and affixes the labels to the packaging. The e-chain® from the E2/000 series takes care of the cable routing.

Fully automated labeller

drylin® linear systems enable flexible adjustment units in this labeller for the pharmaceutical, food and cosmetics industries.

Go to user report

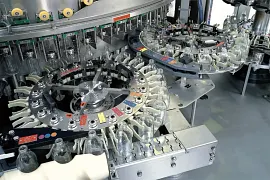

Clamping stars in filling machines

Two-component plastic rollers for clamping stars double the downtime of filling machines.

Go to user report

And even more...

Discover even more successful applications in the beverage, food and packaging industries.

Discover more applicationsConsulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 09:00 - 17:00

Online:

24h