Change Language :

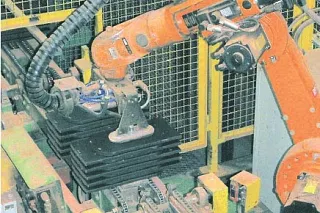

The operating conditions are more than harsh. Brick dust settles everywhere. After the palletising robot was converted to a multidimensional energy supply system, the running times increased considerably.

Multidimensional energy supply in roof tile production

The fine dust generated during the production of roof tiles is a problem for all machines and systems. Nevertheless, production must continue. In order to reliably guarantee the high cycle times during palletising, multidimensional energy supply systems have been in use for over a year. They have proved their worth in the harsh environment right from the start. The service life of the robots has improved significantly.

"We purchase all of our machines and systems from a mechanical engineering company", says Andreas Wals, master electrical engineer at Dachziegelwerke Jungmeier GmbH & Co KG in Struubing. "For this reason, we have no influence on the components used. However, in the course of maintenance and repair work, we replaced the energy supply system on two robots. The solutions originally used could not withstand the harsh conditions on site. And we cannot afford machine downtimes in these difficult economic times."

The multidimensionally movable triflex® R energy supply system has been in use at Jungmeier for over a year, especially for robot applications. It is characterised by high flexibility for complicated movements, even in the 6th axis. The product from igus® GmbH, Cologne, has proven its worth. The closed 'TRC' version is unaffected by the aggressive brick dust. "Our production plant runs in two shifts from 5am to 10pm. Necessary repairs therefore have to take place either at night or at the weekend. As machine downtimes have been significantly reduced, these costly operations are no longer necessary," says Andreas Wals with satisfaction.

The operating conditions are more than harsh. Brick dust settles everywhere. After the palletising robot was converted to a multidimensional energy supply system, the running times increased considerably.

A company with tradition

The company Dachziegelwerke Jungmeier GmbH& Co KG has been around for over 180 years. The company, which is still family-owned today, was founded in 1820 on a site in Straubing on which the Romans were already operating a field tile factory around the time of Christ's birth. 200 employees at the site ensure an annual production of around 50 million pieces. "We specialise exclusively in the production of clay roof tiles", reports Andreas Wals. "This means that around 15,000 roofs of detached and semi-detached houses can be covered safely, reliably and in an environmentally friendly manner."

Ten different basic models and a wide range of accessories are produced in five plants in Straubing with six assembly lines. "Our management recognised the signs of the times at an early stage and invested in the machinery so that today we produce according to the latest trade show state of the art and can hold our own against tough competition", says Andreas Wals.

Two robots are used to palletise the roof tiles. One robot arm picks up the tiles from the belt, rotates them 180° and then stacks them into packs of 8 or 10. This is done at a speed of 2 m/s. The travel is approx. 60 cm. The air is full of brick dust. "We have already used a number of energy chains from other manufacturers and also hose packages, but they have not proved their worth. Due to the extreme movement and the short cycle times, they are usually torn within a very short time. Added to this are the harsh operating conditions. In many cases, the cables were damaged, so that we had to start costly repairs", reports Andreas Wals."After installing the triflex® R, the service life of the two robots has at least tripled, so that the investment pays off for us in any case, both from a technical and economic point of view."

The robust triflex® R chain in use in the roof tile factory.

The multi-dimensional energy supply system is approx. one metre long and is filled with one electric cable and one vacuum line. It does not require additional guidance by spring rods. If required, however, these can be inserted into the application openings provided for this purpose. "Our experience with the new technology has been so good that we will also be using the feeder for seven other robots. Although the cycle times and therefore also the wear are much lower here, we are hoping for an even longer service life," says the master electrical engineer, summarising his concerns.

As the triflex® R has a modular design, individual chain links can be easily replaced. These very good mechanical specifications - impact-resistant, dirt-repellent, robust, abrasion-resistant and warf-resistant - are particularly noticeable in the production conditions of the roof tile factory. The smooth inner and outer contour enables safe sliding over interfering edges and protects the cables at the same time.

Despite dust and dirt, the robot can work reliably with triflex® R feeders.

"We learned about the technical advantages of multidimensional energy supply at a trade fair in autumn 2004", says Andreas Wals. "And we immediately decided to give it a try. We have been using it since the beginning of 2005. During a test phase, we were able to convince ourselves of its advantages in our day-to-day operations."

During a visit on site in Straubing, the responsible igus®® employee, Oliver Köhler, gained an impression of the operating conditions. The chain length and the appropriate connections were determined. A generous payment term during the test phase rounded off the offer. Today, the Jungmeier company keeps the energy supply system with the corresponding connection elements on stock as operating equipment so that it can replace them if necessary or independently convert other robots at any time.

"We are not only focussed on the original equipment manufacturer, but we are also available at any time to provide advice and support for retrofits and conversions", says the technical sales consultant from igus®, Oliver Köhler."And the significant increase in robot running times clearly shows the advantages of the multi-dimensional energy supply system in this application."

You can find more interesting applications from a wide range of areas here

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 09:00 - 17:00

Online:

24h