- Installation size: NEMA 34/flange dimension 86mm

- Protection class: Motor housing IP65 (shaft seal IP52)

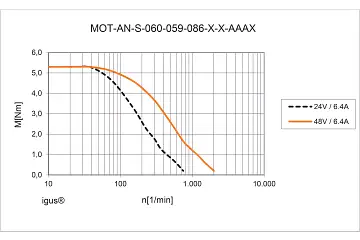

- Holding torque: 5.90Nm

- Nominal current: 6.40A

- Motor connections: Metric M17 connectors (pivoting ± 90°)

- Brake voltage: 24V

- Integrated brake for vertical loads

drylin® E stepper motor with connector, encoder, and brake, NEMA 34

The power pack in the large installation size

The largest stepper motor in the product range impresses with its extremely high torque in the lower speed range. The stepper motor works precisely, is robust, cost-effective and easy to control. It is used in automation, e.g. CNC machine adjustment or robots. The motor is connected via a metric M12(17) connector. This is installed directly on the rear part of the motor housing. The advantage of this is that the motor housing achieves an IP65 degree of protection. The encoder also has a metric M12(17) connector. The encoder is integrated into the motor housing. The two connectors are side by side in the rear part of the motor. In addition, the motor has a brake. This is installed in the motor. The connections for this are in the M17 motor connection. In addition, the motor has a brake. This is also an M8 size metric connector. The brake is also installed in the motor.